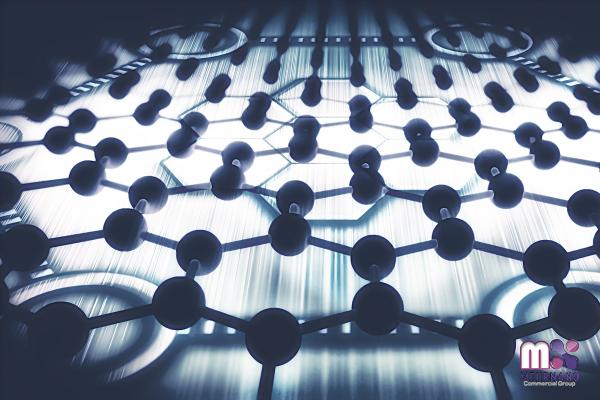

Research shows how using nanostructure can help with reducing the damage susceptibility of asphalt towards moisture. This study investigated the effects of moisture that had penetrated the asphalt-aggregate interface at the atomic level. The molecular interactions of asphalt with limestone and granite were studied using molecular dynamics (MD) simulations. The mineral surface components of limestone and granite were identified using the hyperspectral imaging technique. The relative concentration and radial distribution function (RDF) were used to characterize asphalt component aggregations on aggregate surfaces. We evaluated the adhesion work and the debonding energy in order to investigate the variations in interface energy that occur in asphalt-aggregate systems. According to the findings of the MD analysis, the presence of interfacial moisture modified the asphalt nanostructure and influenced the aggregation state as well as the distribution characteristics of asphalt components near the aggregate surface.  The study also demonstrated that external moisture intruding into the asphalt-aggregate system interface can reduce the concentration distribution of asphalt components with strong polarity on the aggregate surface, the adhesion works of the asphalt-aggregate interface, and the water damage resistance of the asphalt mixture. This was demonstrated by intruding into the asphalt-aggregate system interface. Asphalt mixtures are multiphase composites that contain mineral powder, aggregate, and asphalt in addition to asphalt. Skeleton support and interface bonding work together to keep the mixture’s structure stable. As a result, the performance of the mixture is dependent on both the components that make it up and the interfacial behaviors of the various components. Interfacial interaction describes the complex physicochemical processes that occur at the interface of two different phases of a material. When it comes to asphalt mixtures, there are numerous interfaces, each of which has a direct impact on the overall performance of the mixture. Interface cracks are typically caused by microstructure defects in the material.

The study also demonstrated that external moisture intruding into the asphalt-aggregate system interface can reduce the concentration distribution of asphalt components with strong polarity on the aggregate surface, the adhesion works of the asphalt-aggregate interface, and the water damage resistance of the asphalt mixture. This was demonstrated by intruding into the asphalt-aggregate system interface. Asphalt mixtures are multiphase composites that contain mineral powder, aggregate, and asphalt in addition to asphalt. Skeleton support and interface bonding work together to keep the mixture’s structure stable. As a result, the performance of the mixture is dependent on both the components that make it up and the interfacial behaviors of the various components. Interfacial interaction describes the complex physicochemical processes that occur at the interface of two different phases of a material. When it comes to asphalt mixtures, there are numerous interfaces, each of which has a direct impact on the overall performance of the mixture. Interface cracks are typically caused by microstructure defects in the material.

Damage Susceptibility

When water interacts with asphalt at the interface, it weakens the bond between the asphalt and the aggregate increasing the damage susceptibility, causing moisture damage and stripping in the asphalt to begin at the aggregate’s surface. Nobakht et al. created an adhesive and cohesive moisture damage model capable of predicting the effect of water on asphalt concrete. The results show that the tensile bond strength of the asphalt mixture was significantly reduced as a result of water accumulation at the interface. Wang et al. used the bending beam rheometer method to investigate the effect of moisture on hot mix asphalt. Guo et al. developed an asphalt mixture model and used finite element analysis to evaluate the moisture diffusion model. The results showed that both pressure and temperature had the potential to accelerate the process of moisture diffusion in asphalt mixtures. Luo et al. investigated the diffusion of water vapor into asphalt mixtures under various humidity conditions, and as a result of their findings, they developed two diffusion models. Both simulating intermolecular interactions with finite element simulation technology and directly obtaining nanoscale details of interface cracking through experiments are difficult tasks.  Because asphalt is a nonlinear temperature-sensing material with a complicated and changeable composition, studying its structural characteristics, interface failure mechanisms and micro-scale interactions at the asphalt-aggregate interface phase is difficult. Molecular dynamics (MD) simulation is currently being used in research into the interface interactions and adhesive capabilities of asphalt and aggregate. The atomistic scale MD simulation has been shown to be an effective computational method for simulating the molecular interaction and interface failure of the asphalt-aggregate interface. This was accomplished by employing molecular dynamics. Sun and Wang used MD simulations to investigate how the presence of water affected the adhesive capacity of virgin and aged asphalts with sio2 and calcite aggregate layers. Cui et al. used mineral components such as SiO2 and Al2O3 as representative aggregates in a series of MD simulations. CaO was also used as a component. In order to simulate the effect of moisture intrusion, water molecules were introduced into the interface between the asphalt and the aggregate. Long et al. investigated the effects of moisture and a sodium chloride solution on the surface of SiO2 using simulation results. Liu et al. developed a number of different asphalt-aggregate interface models, and adhesion works were calculated in both wet and dry conditions.

Because asphalt is a nonlinear temperature-sensing material with a complicated and changeable composition, studying its structural characteristics, interface failure mechanisms and micro-scale interactions at the asphalt-aggregate interface phase is difficult. Molecular dynamics (MD) simulation is currently being used in research into the interface interactions and adhesive capabilities of asphalt and aggregate. The atomistic scale MD simulation has been shown to be an effective computational method for simulating the molecular interaction and interface failure of the asphalt-aggregate interface. This was accomplished by employing molecular dynamics. Sun and Wang used MD simulations to investigate how the presence of water affected the adhesive capacity of virgin and aged asphalts with sio2 and calcite aggregate layers. Cui et al. used mineral components such as SiO2 and Al2O3 as representative aggregates in a series of MD simulations. CaO was also used as a component. In order to simulate the effect of moisture intrusion, water molecules were introduced into the interface between the asphalt and the aggregate. Long et al. investigated the effects of moisture and a sodium chloride solution on the surface of SiO2 using simulation results. Liu et al. developed a number of different asphalt-aggregate interface models, and adhesion works were calculated in both wet and dry conditions.  According to Xu et al., moisture intrusion had a negative impact on the adhesive capacity of asphalt-aggregate interfaces. Chu et al. used MD simulations to investigate the adhesion work and bonding energy at the atomic scale using six SiO2 surfaces as model aggregates. Previous research investigated the effects of moisture on asphalt-aggregate interfaces, and their findings were found to be in good agreement with experimental results. It is thus possible to use MD simulations to investigate the water intrusion effect at the nanoscale. Previously, when establishing asphalt-aggregate interface models using MD simulations, aggregates were predominantly chosen from one of five representative oxide crystals (CaO, MgO, SiO2, Al2O3, and Fe2O3). These five oxides, on the other hand, do not exist in minerals independently; rather, they are combined and intertwined with a variety of other substances in their natural state. As a result, the investigation of the interactions of a single oxide crystal with asphalt components using MD simulations affects the accuracy of the actual molecular interactions between asphalt and aggregates. The presence of mineral surface components in aggregates composed of limestone with weakly alkaline chemistry and granite with acid chemistry was determined using the hyperspectral image technique in this study. The primary minerals limestone and granite were used as aggregates in the MD simulations, yielding more accurate results regarding the interactions between asphalt and aggregates.

According to Xu et al., moisture intrusion had a negative impact on the adhesive capacity of asphalt-aggregate interfaces. Chu et al. used MD simulations to investigate the adhesion work and bonding energy at the atomic scale using six SiO2 surfaces as model aggregates. Previous research investigated the effects of moisture on asphalt-aggregate interfaces, and their findings were found to be in good agreement with experimental results. It is thus possible to use MD simulations to investigate the water intrusion effect at the nanoscale. Previously, when establishing asphalt-aggregate interface models using MD simulations, aggregates were predominantly chosen from one of five representative oxide crystals (CaO, MgO, SiO2, Al2O3, and Fe2O3). These five oxides, on the other hand, do not exist in minerals independently; rather, they are combined and intertwined with a variety of other substances in their natural state. As a result, the investigation of the interactions of a single oxide crystal with asphalt components using MD simulations affects the accuracy of the actual molecular interactions between asphalt and aggregates. The presence of mineral surface components in aggregates composed of limestone with weakly alkaline chemistry and granite with acid chemistry was determined using the hyperspectral image technique in this study. The primary minerals limestone and granite were used as aggregates in the MD simulations, yielding more accurate results regarding the interactions between asphalt and aggregates.  The peak asphaltene value at 10-14 after water addition was found to be significantly higher than the value obtained when the asphalt and calcite were dry. This was due to the fact that water and asphaltene were electrostatically attracted to one another, resulting in an increase in asphaltene concentration on the calcite surface. It is possible that the decrease in peak asphaltene value at 30 degrees is due to the presence of water, which can significantly remove asphalt film from mineral surfaces. Moisture reduced the peak concentration values of many resin peaks, resulting in a more even distribution of resin concentration across the calcite surface. This was true for the resin, which had a polarization capacity only slightly lower than asphaltene. Water was discovered to reduce the amount of resin concentration near the surface of weakly alkaline minerals, resulting in a reduction in mineral-asphalt adhesion. Moisture caused a slight decrease in the amount of saturated aggregation on the surface of the aggregate, while its diffusion degree increased. When free water from the environment penetrated the asphalt-albite interface, two things happened: the concentration of saturating decreased near the aggregate surface and the concentration of asphaltene increased.

The peak asphaltene value at 10-14 after water addition was found to be significantly higher than the value obtained when the asphalt and calcite were dry. This was due to the fact that water and asphaltene were electrostatically attracted to one another, resulting in an increase in asphaltene concentration on the calcite surface. It is possible that the decrease in peak asphaltene value at 30 degrees is due to the presence of water, which can significantly remove asphalt film from mineral surfaces. Moisture reduced the peak concentration values of many resin peaks, resulting in a more even distribution of resin concentration across the calcite surface. This was true for the resin, which had a polarization capacity only slightly lower than asphaltene. Water was discovered to reduce the amount of resin concentration near the surface of weakly alkaline minerals, resulting in a reduction in mineral-asphalt adhesion. Moisture caused a slight decrease in the amount of saturated aggregation on the surface of the aggregate, while its diffusion degree increased. When free water from the environment penetrated the asphalt-albite interface, two things happened: the concentration of saturating decreased near the aggregate surface and the concentration of asphaltene increased.  This was evident at the asphalt-albite interface. The reason for this is that interfacial moisture can cause the non-polar light component to saturate away from the mineral, attracting asphaltene to the aggregate surface via the charge effect. Moisture was discovered to have an effect on the appearance time and concentration of g(r) peaks in SARA components. To put it another way, while water can increase the concentration of polar substances on the surface of minerals, it also increases the distance between asphalt and acid minerals and reduces the concentration distribution between the two. These factors contribute to a decrease in the adhesive capacity of the asphalt-aggregate interface. The relative concentrations of SARA components revealed that the concentrations of polar substances in asphalt on the aggregate surface gradually decreased after water penetrated the asphalt-aggregate interface. This was demonstrated by the acronym SARA, which represented the relative concentrations of SARA components. The presence of water during this time caused the asphalt components to separate from the aggregate, resulting in movement. These occurrences were consistent with what the RDF curve observations revealed.

This was evident at the asphalt-albite interface. The reason for this is that interfacial moisture can cause the non-polar light component to saturate away from the mineral, attracting asphaltene to the aggregate surface via the charge effect. Moisture was discovered to have an effect on the appearance time and concentration of g(r) peaks in SARA components. To put it another way, while water can increase the concentration of polar substances on the surface of minerals, it also increases the distance between asphalt and acid minerals and reduces the concentration distribution between the two. These factors contribute to a decrease in the adhesive capacity of the asphalt-aggregate interface. The relative concentrations of SARA components revealed that the concentrations of polar substances in asphalt on the aggregate surface gradually decreased after water penetrated the asphalt-aggregate interface. This was demonstrated by the acronym SARA, which represented the relative concentrations of SARA components. The presence of water during this time caused the asphalt components to separate from the aggregate, resulting in movement. These occurrences were consistent with what the RDF curve observations revealed.

Asphalt Moisture Damage

The primary cause of the asphalt-aggregate system’s demise was a loss of adhesion between the asphalt and the aggregate. The MD method was used to accurately simulate asphalt-mineral interface adhesion. This enabled an effective analysis of the interface adhesion failure behavior as well as the strength failure mechanism due to moisture penetration into the asphalt-aggregate interface at the microscale. This could provide researchers with reasonable technical methods for improving asphalt-aggregate system adhesion, increasing asphalt mixture water damage resistance, and preventing water damage to asphalt pavements. Under dry conditions, the adhesion works of asphalt-calcite and asphalt-albite interfaces were found to be 467.81 and 551.01 kcal/mol, respectively. These values were discovered to be slightly higher than those obtained for the asphalt-calcite system. Although the acidic mineral albite (Na2OAlO36SiO2) contained more SiO2, which contributed less to adhesion work, it also contained Na+, which had a stronger polarization ability than Ca2+. This was the cause of the phenomenon.  Because of the strong electrostatic attraction of Na+ toward asphaltene and resin with strong polarity in asphalt, the adhesion work at the asphalt-albite interface was significantly increased. As a result, the total amount of adhesion work increased significantly. When moisture was introduced into the interface between the asphalt and the aggregate, the asphalt-calcite adhesion work was reduced to 416.51 kcal/mol, and the W value reached 11.0%. The asphalt-albite adhesion work, on the other hand, was reduced to 444.50 kcal/mol, while the W value remained at 19.3%. The presence of moisture hampered the ability of aggregate and asphalt to debond, while acid mineral albite’s adhesion work was greatly reduced. This was due to the presence of numerous silica in albite, each of which had strong polarization properties in relation to water. Hyperspectral images are increasingly being used in mineral research due to the nearly continuous spectral information they provide. As a result, hyperspectral image technology was used to determine the surface compositions of minerals such as limestone and granite. The first step, was to capture hyperspectral images with a Pika XC2 hyperspectral imager. The images were then loaded onto a platform known as ENVI, which stands for Environment for Visualizing Images. Hyperspectral images have massive data volumes, making data processing extremely difficult. As a result, the Minimum Noise Fraction (MNF) rotation tool was used to distinguish between reliable estimations and random noises of data dimensionality present in signal information.

Because of the strong electrostatic attraction of Na+ toward asphaltene and resin with strong polarity in asphalt, the adhesion work at the asphalt-albite interface was significantly increased. As a result, the total amount of adhesion work increased significantly. When moisture was introduced into the interface between the asphalt and the aggregate, the asphalt-calcite adhesion work was reduced to 416.51 kcal/mol, and the W value reached 11.0%. The asphalt-albite adhesion work, on the other hand, was reduced to 444.50 kcal/mol, while the W value remained at 19.3%. The presence of moisture hampered the ability of aggregate and asphalt to debond, while acid mineral albite’s adhesion work was greatly reduced. This was due to the presence of numerous silica in albite, each of which had strong polarization properties in relation to water. Hyperspectral images are increasingly being used in mineral research due to the nearly continuous spectral information they provide. As a result, hyperspectral image technology was used to determine the surface compositions of minerals such as limestone and granite. The first step, was to capture hyperspectral images with a Pika XC2 hyperspectral imager. The images were then loaded onto a platform known as ENVI, which stands for Environment for Visualizing Images. Hyperspectral images have massive data volumes, making data processing extremely difficult. As a result, the Minimum Noise Fraction (MNF) rotation tool was used to distinguish between reliable estimations and random noises of data dimensionality present in signal information.  Following that, the Pure Pixel Index (PPI) tool was used to isolate end members within MNF images. Furthermore, spectral mixing space n-dimensional visualization, an image classification interaction method, was used to extract the spectrum of the pixel with the purest values. Mineral standard spectral library files were chosen to be used as a contrast spectral library when determining the surface components of aggregates using spectral analyses. The spectral angle mapper (SAM) algorithm, which measures the degree of similarity between the spectral components of an image and those of a reference spectral, is based on calculating the spectral angle between two vectors. The spectral feature fittings (SFF) algorithm, on the other hand, involves the removal of absorption features between the reference spectrum and each image spectrum, as well as the cutting off of each original image pixel’s spectrum and continuum curve. The SAM and SFF algorithms were used to identify mineral components on the aggregate surface. These algorithms were used to compare the image’s spectrum to the standard spectrum. The current study used hyperspectral image technology to investigate the mineral compositions of limestone and granite surfaces. The MD simulation was then used to assess the impact of the moisture that penetrated the asphalt-aggregate interface. This was accomplished by comparing the results of the two tests. Based on the simulation results, the following observations and inferences were made:

Following that, the Pure Pixel Index (PPI) tool was used to isolate end members within MNF images. Furthermore, spectral mixing space n-dimensional visualization, an image classification interaction method, was used to extract the spectrum of the pixel with the purest values. Mineral standard spectral library files were chosen to be used as a contrast spectral library when determining the surface components of aggregates using spectral analyses. The spectral angle mapper (SAM) algorithm, which measures the degree of similarity between the spectral components of an image and those of a reference spectral, is based on calculating the spectral angle between two vectors. The spectral feature fittings (SFF) algorithm, on the other hand, involves the removal of absorption features between the reference spectrum and each image spectrum, as well as the cutting off of each original image pixel’s spectrum and continuum curve. The SAM and SFF algorithms were used to identify mineral components on the aggregate surface. These algorithms were used to compare the image’s spectrum to the standard spectrum. The current study used hyperspectral image technology to investigate the mineral compositions of limestone and granite surfaces. The MD simulation was then used to assess the impact of the moisture that penetrated the asphalt-aggregate interface. This was accomplished by comparing the results of the two tests. Based on the simulation results, the following observations and inferences were made:  According to hyperspectral and image processing findings, the primary mineral components of limestone are calcite, dolomite, and magnesite, with calcite accounting for 73.2% of the total. Furthermore, quartz, biotite, and albite are the primary minerals that makeup granite, with albite accounting for 68.8% of the total. Because of this, calcite and albite were used as aggregates in MD simulations. Asphaltene and resin tend to accumulate near the surface of weakly alkaline aggregates due to charge interactions. Bitumen-acid mineral molecular interactions were relatively weak, and the distribution of SARA components near the surface of acid aggregates was more uniform. The presence of moisture at the asphalt-aggregate interface has the potential to change the asphalt’s nanostructure as well as the distribution of SARA components on the aggregate surface. In the presence of interfacial moisture, the amount of work required for asphalt-aggregate adhesion was reduced. Both limestone and granite experienced a decrease in adhesion works, with limestone experiencing an 11.0 decrease and granite experiencing a 19.3% decrease. That is, the water damage resistance of an asphalt mixture was determined by the adhesion work and debonding energy between the asphalt and aggregate when water was introduced into the asphalt-aggregate interface system. This was due to water weakening the bond between the asphalt and aggregate.

According to hyperspectral and image processing findings, the primary mineral components of limestone are calcite, dolomite, and magnesite, with calcite accounting for 73.2% of the total. Furthermore, quartz, biotite, and albite are the primary minerals that makeup granite, with albite accounting for 68.8% of the total. Because of this, calcite and albite were used as aggregates in MD simulations. Asphaltene and resin tend to accumulate near the surface of weakly alkaline aggregates due to charge interactions. Bitumen-acid mineral molecular interactions were relatively weak, and the distribution of SARA components near the surface of acid aggregates was more uniform. The presence of moisture at the asphalt-aggregate interface has the potential to change the asphalt’s nanostructure as well as the distribution of SARA components on the aggregate surface. In the presence of interfacial moisture, the amount of work required for asphalt-aggregate adhesion was reduced. Both limestone and granite experienced a decrease in adhesion works, with limestone experiencing an 11.0 decrease and granite experiencing a 19.3% decrease. That is, the water damage resistance of an asphalt mixture was determined by the adhesion work and debonding energy between the asphalt and aggregate when water was introduced into the asphalt-aggregate interface system. This was due to water weakening the bond between the asphalt and aggregate.

Your comment submitted.