In recent years, technological advancements have paved the way for groundbreaking innovations in various industries. One such advancement is the development of nano diamond products DAC (Diamond Aerosol Coating). Nano diamond products DAC have taken center stage as a game-changer in multiple sectors, offering improved performance and durability previously unseen. This article explores the features and benefits of nano diamond products DAC, along with its potential applications and impact on various industries. Unprecedented Durability and Enhanced Performance: Nano diamond products DAC are engineered by integrating nanodiamond particles into a coating matrix. These particles possess remarkable strength and hardness, which translates into unrivaled durability. This coating has the ability to adhere to various substrates, including metals, ceramics, and polymers. Due to their high wear resistance and ultra-low friction characteristics, nano diamond products DAC can substantially extend the lifespan of components and improve their overall performance.

.

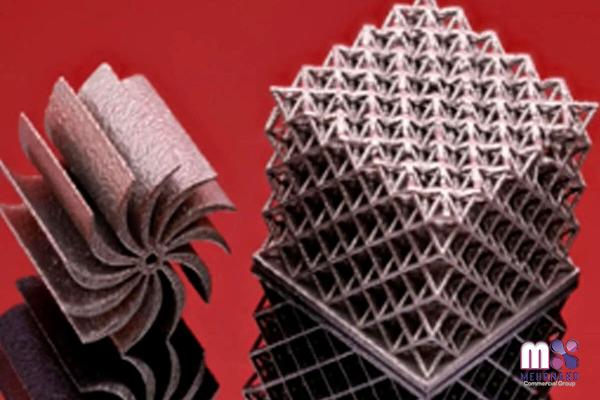

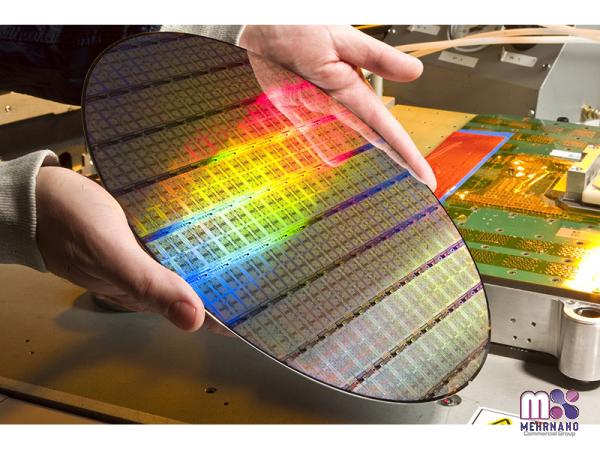

These coatings excel in extreme environments, providing protection against erosion, corrosion, and high-temperature degradation. Applications across Multiple Industries: The versatility of nano diamond products DAC makes them suitable for a wide range of industries. In the automotive sector, DAC coatings can be applied to engine components, reducing friction, enhancing fuel efficiency, and increasing engine longevity. In the aerospace industry, DAC coatings can be used on turbine blades, reducing engine friction, increasing efficiency, and ultimately leading to fuel savings. DAC coatings can also be applied to cutting tools, significantly improving tool life, reducing machining costs, and achieving better precision in manufacturing industries. The energy sector can benefit from DAC coatings by improving the performance and durability of wind turbine components, which leads to increased energy generation and reduced maintenance requirements.

These coatings excel in extreme environments, providing protection against erosion, corrosion, and high-temperature degradation. Applications across Multiple Industries: The versatility of nano diamond products DAC makes them suitable for a wide range of industries. In the automotive sector, DAC coatings can be applied to engine components, reducing friction, enhancing fuel efficiency, and increasing engine longevity. In the aerospace industry, DAC coatings can be used on turbine blades, reducing engine friction, increasing efficiency, and ultimately leading to fuel savings. DAC coatings can also be applied to cutting tools, significantly improving tool life, reducing machining costs, and achieving better precision in manufacturing industries. The energy sector can benefit from DAC coatings by improving the performance and durability of wind turbine components, which leads to increased energy generation and reduced maintenance requirements.

..

Environmental Advantages: Nano diamond products DAC also present environmental advantages. Improved durability and performance lead to reduced waste and energy consumption throughout the lifecycle of coated components. Longer-lasting products minimize the need for frequent replacements, reducing the overall environmental footprint. Furthermore, the low-friction characteristics of DAC coatings translate into decreased energy consumption in various applications, contributing to a greener and more sustainable future. The Future of Nano Diamond Products DAC: The rapid growth and implementation of nano diamond products DAC are only expected to continue. Researchers and manufacturers are constantly exploring new application possibilities and refining the technology to unlock its full potential.

Environmental Advantages: Nano diamond products DAC also present environmental advantages. Improved durability and performance lead to reduced waste and energy consumption throughout the lifecycle of coated components. Longer-lasting products minimize the need for frequent replacements, reducing the overall environmental footprint. Furthermore, the low-friction characteristics of DAC coatings translate into decreased energy consumption in various applications, contributing to a greener and more sustainable future. The Future of Nano Diamond Products DAC: The rapid growth and implementation of nano diamond products DAC are only expected to continue. Researchers and manufacturers are constantly exploring new application possibilities and refining the technology to unlock its full potential.

…

As industries strive for increased efficiency, reduced waste, and enhanced performance, nano diamond products DAC offer a compelling solution. With ongoing advancements, DAC coatings have the potential to revolutionize a range of industries by pushing the boundaries of what is currently deemed possible. Conclusion: Nano diamond products DAC have emerged as a game-changing technology, offering industries improved performance, enhanced durability, and environmental advantages. Their unique properties make them suitable for various applications, from automotive and aerospace to energy and manufacturing. As this revolutionary coating continues to evolve, nano diamond products DAC have the potential to redefine industry standards and shape the way we approach design, engineering, and manufacturing. The future holds immense possibilities for this breakthrough technology, promising a more efficient, durable, and sustainable world.

As industries strive for increased efficiency, reduced waste, and enhanced performance, nano diamond products DAC offer a compelling solution. With ongoing advancements, DAC coatings have the potential to revolutionize a range of industries by pushing the boundaries of what is currently deemed possible. Conclusion: Nano diamond products DAC have emerged as a game-changing technology, offering industries improved performance, enhanced durability, and environmental advantages. Their unique properties make them suitable for various applications, from automotive and aerospace to energy and manufacturing. As this revolutionary coating continues to evolve, nano diamond products DAC have the potential to redefine industry standards and shape the way we approach design, engineering, and manufacturing. The future holds immense possibilities for this breakthrough technology, promising a more efficient, durable, and sustainable world.

Your comment submitted.